Transform Your Business with ToTMaN ERP Solutions

Automate, Track, and Manage Orders Efficiently with Our All-in-One Solution

ToTMaN offers a range of powerful, customizable software solutions designed to meet the unique needs of modern businesses. Our products are built to streamline operations, improve efficiency, and enhance decision-making, giving our clients the competitive edge they need to thrive in today’s dynamic market.

ENSI

Enviro Signer LV enhances manufacturing sales with efficient signing, digital invoice emailing, and seamless integration. It ensures accuracy, transparency, and quick processing for streamlined sales operations.

ENSI 1.0

Enviro Signer 1.0 is an innovative tool that makes the sales process for manufacturing organizations efficient and cost-effective. It offers a simple way to sign invoices with complete accuracy and digital transparency.

ENSI 2.0

Enviro Signer 2.0 is a modern E-invoicing solution that simplifies the invoicing process for businesses. EnSi 2.0 saves time, reduces effort, and enhances overall efficiency. It Registers invoices, generates IRNs/QR codes, streamlines invoicing.

IQVT

The Invoice Quantity Verification tool verifies physical quantities against invoiced quantities to ensure accuracy in material transactions, minimize discrepancies, and enhance accountability in the supply chain process.

SOMS

The Sales Order Management System is an automated invoicing solution tailored for automobile ancillaries. It simplifies order processing, invoicing, and tracking to improve efficiency and accuracy in managing sales orders.

WORK ORDER

Work Order Management system that handles everything from order creation to completion tracking. Monitor resource allocation, track material consumption, and manage production schedules in real-time while ensuring optimal workflow efficiency.

CONSUMPTION DETAIL

Track & manage your raw material consumption with precision through automated real-time monitoring. Get instant visibility into material variances, wastage patterns, and inventory impacts to optimize your production costs and resource utilization.

PRODUCTION UPDATE

Keep your production tracking seamless with real-time updates on work order progress and machine utilization. Instantly monitor production status, record actual outputs, and identify bottlenecks to maintain optimal production flow.

FINISHED GOODS QC

Ensure product quality with our robust QC module that facilitates comprehensive quality checks and testing protocols for finished goods. Track quality metrics, manage inspection workflows, and maintain detailed records of quality parameters to guarantee your products meet specified standards.

STOCK MONITOR

Monitor inventory levels in real-time with comprehensive visibility across raw materials, work-in-progress, and finished goods. Track stock movements, get instant alerts on low inventory, and maintain optimal stock levels to prevent production delays.

PRODUCTION LOSS TRACKER

Track and analyze production losses with detailed insights into wastage, rejects, and process inefficiencies. Get actionable data on loss patterns to implement targeted improvements and minimize production waste.

VMMS

Vendor Material Management System (VMMS) connects manufacturers and vendors, improving accountability and traceability. It simplifies Purchase Orders, Shipping Notices, and tracking with real-time visibility and fewer errors.

GOODS RECEIPT

Streamline your inventory receiving process with automated goods receipt tracking and comprehensive quality inspection workflows. Manage vendor deliveries, record item quantities, and maintain detailed documentation of received materials while ensuring compliance with purchase specifications.

GR INSPECTION

Ensure quality standards with comprehensive inspection workflows that validate incoming materials against specifications. Track defects, manage vendor quality metrics, and automate the approval process for seamless inventory acceptance.

GR TO STORE

Efficiently manage material transfers from goods receipt to warehouse locations with automated tracking and bin allocation. Record storage locations, update inventory levels, and maintain complete traceability of received goods throughout your facility.

MATERIAL REQUEST

Track request status, maintain audit trails, and ensure timely fulfillment of material needs across departments.

MATERIAL ISSUE

Manage material disbursement with automated tracking of item transfers from stores to production departments. Control inventory accuracy and maintain detailed records of material movements while ensuring proper documentation of each transaction.

PURCHASE ORDER MANAGEMENT

Control your purchasing process with complete management of purchase orders, from creation to fulfillment. Automate order generation, track vendor performance, and maintain full visibility of order status while adhering to procurement policies.

MOVE TO MAINTENANCE

Automate the tracking of equipment as it moves between departments, providing real-time updates on its location and status. Record the condition of the equipment, create a complete movement history, and enforce standardized handover processes for seamless asset transitions.

MAINTENANCE TO PRODUCTION

Ensure a smooth transition of equipment back to production following maintenance through automated status tracking and readiness checks. Monitor equipment performance data and keep thorough records of all maintenance performed to guarantee peak operational readiness.

MOLD MACHINE IN REGISTER

Record and monitor all mold and die equipment as it enters the production area, including detailed documentation of their specifications and current state. Preserve precise records of tool locations, usage history, and performance data for effective resource allocation.

MACHINE OUT REGISTER

Document and track the removal of mold equipment from production, automatically logging usage metrics and any required maintenance. Oversee tool lifecycles, maintenance schedules, and location information to guarantee proper equipment control.

SPARE REPORT

Analyze spare parts inventory, usage trends, and replenishment needs with detailed analytics and automated notifications. Maintain optimal stock levels of critical spares and monitor their availability for preventative maintenance activities.

MACHINE MONITOR

Visualize real-time machine performance, operational metrics, and maintenance status using comprehensive dashboard analytics. Assess equipment health, identify anomalies, and schedule preventative maintenance based on actual operating patterns.

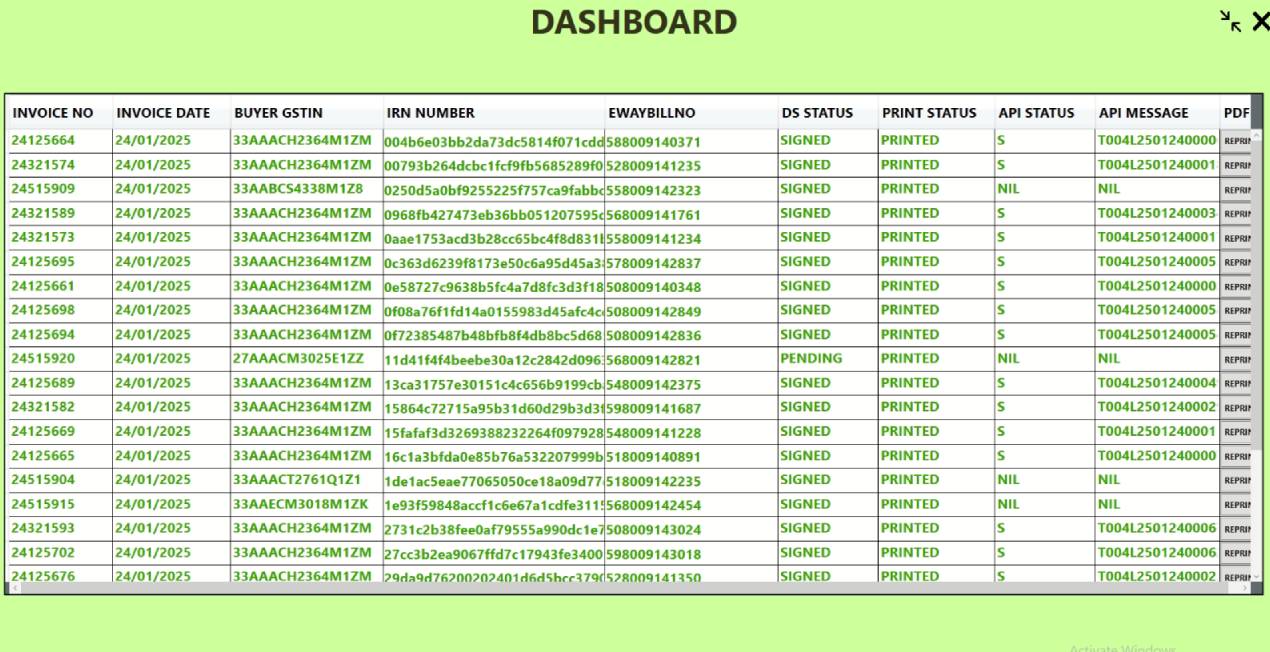

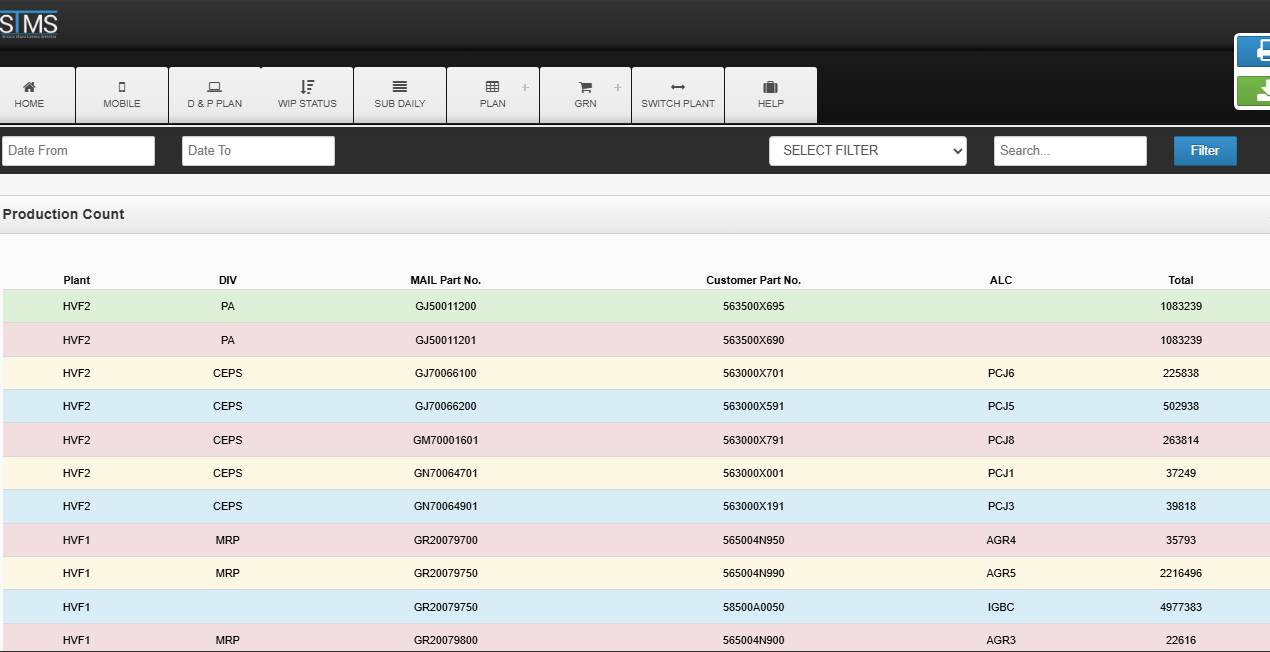

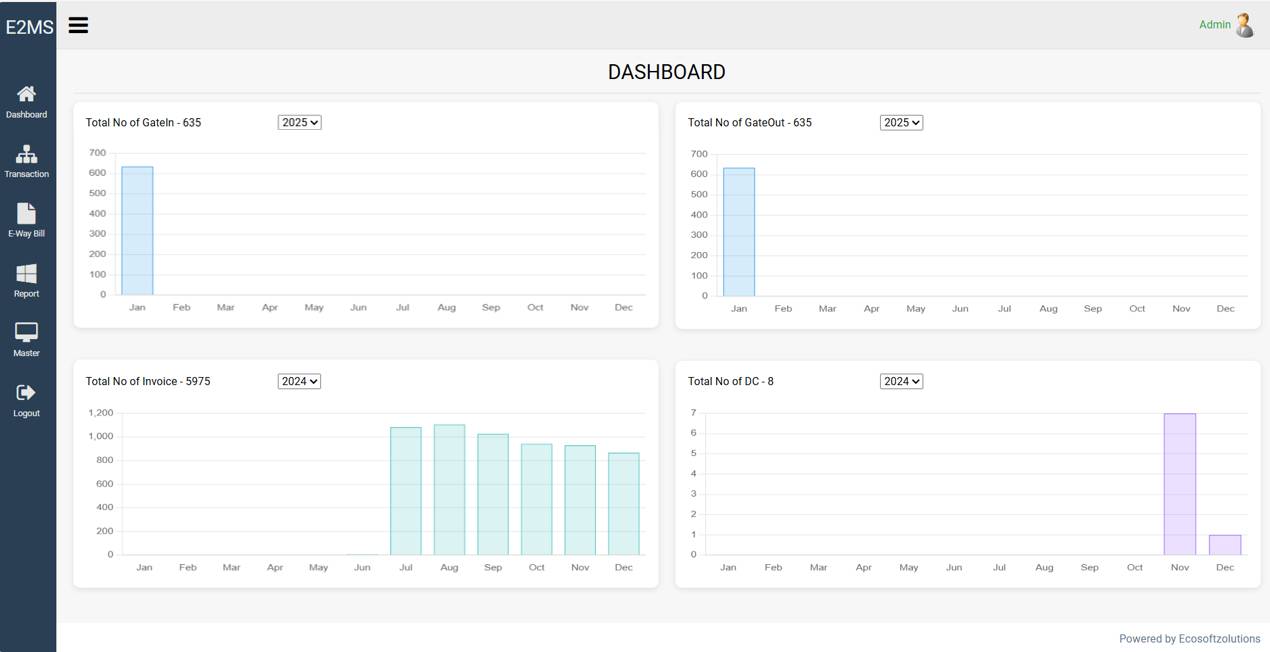

Product Dashboard View

Why Choose Our ERP Products

Ecosoft’s innovative software suite is designed to solve real business challenges with intelligent, scalable solutions. With tools for order management, customer relationship building, and data-driven insights, we help you drive efficiency and maximize growth potential.

- Built with the user in mind, our products offer intuitive interfaces that make complex processes easy to manage.

- We prioritize data security and system reliability, giving you peace of mind that your information is safe.

- Our solutions grow with your business, ensuring that you can adapt to changes and expand without disruption.

Transform Your Workflow Book a Demo of Ecosoft

Ready to optimize your operations ?

Book a demo with Ecosoft to get an in-depth look at our powerful solutions. Our team will provide a step-by-step walkthrough of our platform’s features, answering your questions and showing you how Ecosoft can make a real impact on your business’s efficiency and growth.